Wood Plastic Composite

Wood Plastic Composite Specification

- Technology

- Extrusion Molding

- Power Source

- Electric

- Operating Pressure

- Standard Atmospheric

- Control System

- PLC Controlled

- Machine Type

- Decking Extruder

- Accessories Type

- Deck Clips, End Caps

- Surface Treatment

- Polished

- Automation Grade

- Automatic

- Accuracy

- High Precision

- Type

- Decking Board

- Material

- Wood Plastic Composite

- Function

- Outdoor Flooring

- Application

- Patios, Walkways, Gardens

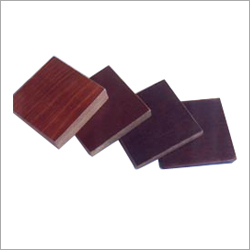

About Wood Plastic Composite

Our firm has attained a respectable position in this domain by consistently manufacturing and supplying high quality range of Wood Plastic Composite, Wood Plastic Composite Material and Wood Plastic Composite Products. These products are manufactured sturdily and precisely by making use of optimum quality permawood and synthetic resin based material in divergent sizes, colors and dimensions in adherence with the quality norms laid down by the industry. The Wood Plastic Composite are suitably utilized for parcel trays, instrument panels, floorings and coil support platforms.

Features:

-

High durability

-

Smooth finish

-

Sturdy structure

Advanced Extrusion Molding Technology

Our WPC decking boards utilize the latest extrusion molding technology paired with high-precision, automated machinery for consistent, reliable production. The process ensures each board meets strict standards for strength and durability, further enhanced with a polished finish that offers both visual appeal and functional longevity. This approach guarantees excellent product performance for demanding outdoor applications.

Designed for Versatile Outdoor Applications

Engineered for patios, walkways, and gardens, our WPC decking is perfect for transforming outdoor spaces. The combination of wood fiber and plastic makes it resistant to moisture, UV rays, and everyday wear. Installation is straightforward with included accessories such as deck clips and end caps, making this flooring solution both practical and aesthetically pleasing.

FAQs of Wood Plastic Composite:

Q: How is Wood Plastic Composite decking manufactured?

A: Wood Plastic Composite decking is produced through an extrusion molding process using a high-precision, automatic decking extruder. The machine blends wood fibers and plastic, shaping them into boards, all managed by a PLC-controlled system for accuracy and consistency.Q: What is the primary application of WPC decking boards?

A: WPC decking boards are specifically designed for outdoor flooring purposes, making them ideal for patios, walkways, and gardens. They are suitable for both residential and commercial settings due to their durability and resilience.Q: When should I consider using WPC decking over traditional wood?

A: WPC decking should be chosen when you desire a low-maintenance, moisture-resistant, and long-lasting flooring solution for outdoor spaces. Its composite material outperforms traditional wood in exposed environments by resisting rot, splinters, and warping.Q: Where are these decking boards typically installed?

A: These decking boards are commonly installed in outdoor settings such as patios, garden paths, terraces, and walkways. They can be used in both private homes and commercial outdoor venues.Q: What is the installation process for WPC decking boards?

A: The installation process involves securely fitting the decking boards using specialized deck clips and finishing with end caps. The boards are easy to cut and fasten, and the system allows for efficient, precise placement on prepared surfaces.Q: How does surface treatment benefit the decking boards?

A: The polished surface of the decking boards not only enhances their appearance but also provides added protection against moisture and stains. This treatment ensures the boards retain their aesthetic appeal over time, even under frequent use and changing weather conditions.Q: What are the main advantages of choosing WPC decking from an Indian exporter, manufacturer, and supplier?

A: Choosing WPC decking from a reputable Indian exporter, manufacturer, and supplier ensures you receive a high-quality, precisely engineered product with reliable after-sales support. It also guarantees competitive pricing and adherence to international standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wood Based Composite Material Category

Composite Material Castings

Application : Machinery, Pumps, Industrial Equipment

Power Source : Electric

Control System : PLC Controlled

Function : Structural and Protective

Features : Corrosion Resistant, Lightweight, High Impact Strength

Material : Fiber Reinforced Polymer (FRP) Composite

Industrial Composite Products

Application : Chemical Industry, Power Plants, Structural Support, Machine Components

Power Source : Electric

Control System : PLC Controlled / Manual

Function : Mechanical Strength Enhancement & Corrosion Resistance

Material : FRP (Fiber Reinforced Plastic), GRP, Customized Polymer Resin

Electrical Wood Material

Application : Electrical Panels, Switch Boards

Power Source : None

Control System : None

Function : Electrical Insulation

Features : Moisture Resistant, Termite Proof, Durable

Vacuum Impregnated Material

Application : Auto Components, Electrical Castings, Powder Metallurgy Parts

Power Source : Electric

Control System : PLC Controlled

Function : Seal Porosity, Improve Leak Tightness

Features : Efficient Sealing, High Reliability, Enhanced Component Life

Material : Porous Metal/Alloys

Send Inquiry

Send Inquiry