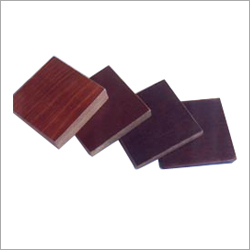

Electrical Wood Material

Electrical Wood Material Specification

- Accessories Type

- Mounting Strips, Covers

- Features

- Moisture Resistant, Termite Proof, Durable

- Surface Treatment

- Polished

- Machine Type

- Manual Fabrication

- Control System

- None

- Operating Pressure

- Ambient

- Automation Grade

- Manual

- Power Source

- None

- Type

- Insulating Material

- Function

- Electrical Insulation

- Application

- Electrical Panels, Switch Boards

- Voltage

- Up to 1000V

About Electrical Wood Material

Our reputed firm manufactures and supplies immaculate range of robust Electrical Wood Material that are majorly used in making pressure pieces, cable supporting beams, limbs, spacer blocks in oil immersed transformer and clamps in instrument transform. We use supreme quality birch and willow timbers while processing this Electrical Permawood. These are thoroughly examined and are made to go through rigorous course of boiling, rotary cutting and drying. Our Electrical Wood Material has good dimensional stability, weight ratio, dielectric properties and high strength

Features

-

Moderate specific gravity

-

Easy vacuum drying

-

High mechanical properties

Further Details:

Components like coil clamping Rings, coil support Platform, etc having application in Transformers upto 400Kv

Superior Electrical Insulation

This wood material features excellent insulating capabilities, making it suitable for applications demanding high voltage protection up to 1000V. Its polished surface further contributes to reliable performance in electrical panels and switches.

Engineered for Durability

Tested for moisture resistance and termite protection, our electrical wood material stands up to demanding environments. Its robust construction ensures longevity, even under persistent manual operations and ambient pressures.

Versatile Accessories for Easy Mounting

Supplied as mounting strips and covers, the material integrates seamlessly into various electrical installations. Exporters, manufacturers, and suppliers in India benefit from its hassle-free manual fabrication and adaptable design.

FAQs of Electrical Wood Material:

Q: How does the electrical wood material provide insulation in electrical panels and switch boards?

A: The materials natural insulating properties, combined with its polished surface treatment, effectively prevent electrical conduction, making it ideal for separating conductive components in panels and boards up to 1000V.Q: What are the main benefits of using this insulating wood material in manual fabrication projects?

A: Its moisture-resistant and termite-proof features ensure long-lasting durability, while easy handling and adaptability make it highly suitable for manual fabrication of mounting strips and covers.Q: When should I consider using this product over conventional insulation materials?

A: This electrical wood material is preferred when you require robust insulation, environmental resistance, and manual fabrication capabilities without the need for automation or power sources.Q: Where can the electrical wood material be used within industrial and electrical settings?

A: You can use it inside electrical panels, switch boards, and machine enclosures as mounting strips or covers, particularly where ambient pressure and manual assembly are standard.Q: What is the fabrication process for mounting strips and covers using this material?

A: Fabrication is performed manually, typically involving cutting, shaping, and polishing pieces to desired sizes for mounting or covering electrical components without the need for automated equipment.Q: How does moisture and termite resistance benefit long-term installation?

A: Moisture and termite resistance safeguard the material from environmental degradation, especially in humid or pest-prone areas, ensuring reliable performance and low maintenance over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wood Based Composite Material Category

Composite Material Castings

Application : Machinery, Pumps, Industrial Equipment

Material : Fiber Reinforced Polymer (FRP) Composite

Function : Structural and Protective

Power Source : Electric

Control System : PLC Controlled

Technology : Resin Transfer Molding (RTM)

Wood Plastic Composite

Application : Patios, Walkways, Gardens

Material : Wood Plastic Composite

Function : Outdoor Flooring

Power Source : Electric

Control System : PLC Controlled

Technology : Extrusion Molding

Industrial Composite Products

Application : Chemical Industry, Power Plants, Structural Support, Machine Components

Material : FRP (Fiber Reinforced Plastic), GRP, Customized Polymer Resin

Function : Mechanical Strength Enhancement & Corrosion Resistance

Power Source : Electric

Control System : PLC Controlled / Manual

Technology : Pultrusion / Filament Winding / Molding

Vacuum Impregnated Material

Application : Auto Components, Electrical Castings, Powder Metallurgy Parts

Material : Porous Metal/Alloys

Function : Seal Porosity, Improve Leak Tightness

Power Source : Electric

Control System : PLC Controlled

Send Inquiry

Send Inquiry