Glass Composite Materials

Glass Composite Materials Specification

- Surface Treatment

- Polished/Matte Finish

- Accessories Type

- Cutting, Drilling, Mounting Accessories

- Operating Pressure

- Ambient

- Control System

- PLC / Manual

- Features

- Corrosion Resistant, High Dielectric Strength, Durable

- Power Source

- Electric

- Type

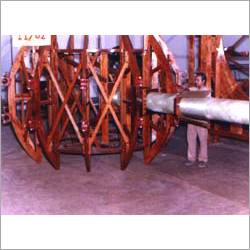

- Glass Fiber Reinforced Composite

- Material

- Glass Fiber, Resin

- Function

- High Strength Structural Support

- Application

- Industrial, Construction, Electrical Insulation

About Glass Composite Materials

Product Application

Our products find application in almost every industry. The industries we have served in the past include -

| Electrical | Transformer, Switch Gear, Generator, Motor, Control Panel, etc. |

| Defence | Established Applications in Military, Navy & AirForce |

| Railways | Coach Buildings, Electrical Equipments, Traction Equipments, Rail Track components etc. |

| Automobile | Instrument Panel, Parcel Tray, Flooring, Under Bonnet Applications, Bumpers, etc. |

| Foundries | Match Plates & Pattern etc. |

| Forgings | Pattern Making, etc. |

| Textile machineries | Picking Sticks, etc for High Speed Automatic Looms. |

| Telecommunications | Underground Cable Covers & Casings, Joint Boxes, Telephone Booths etc. |

| Chemical | Pipelines, Tanks, Cryogenic Applications, etc. |

| Petroleum | Off-shore applications, pipelines, Non-corrosive doors, Partition, etc. |

| Construction | Doors, Flooring Material, etc. |

| Atomic Energy | Neutron Shielding Application. |

Superior Mechanical Performance

Our glass fiber reinforced composites offer outstanding mechanical stability, with high tensile and flexural strength. These properties make them especially suitable for environments demanding resilience and long-term reliability under variable loads.

Versatile Surface Finishes

Choose from polished or matte finishes to suit your projects aesthetic or functional requirements. Both finishing types are expertly treated to ensure longevity, easy cleaning, and resistance against surface wear or weathering.

Exceptional Electrical Insulation

The materials high dielectric strength makes it ideal for electrical insulation applications, protecting circuits and components in control systems and offering safety for high-voltage environments.

FAQs of Glass Composite Materials:

Q: How are glass composite materials with surface treatment used in industrial applications?

A: These composites are employed as structural supports, panels, and insulation boards in industrial settings, leveraging their strength, durability, and corrosion resistance for long-lasting performance in demanding environments.Q: What benefits does a glass fiber reinforced composite offer over traditional materials?

A: Compared to metals and plain plastics, glass fiber reinforced composites provide superior strength-to-weight ratio, higher dielectric properties, better corrosion resistance, and longer lifespan in harsh conditions.Q: When is it recommended to use a polished finish versus a matte finish for these composites?

A: Polished finishes are suitable for environments where easy cleaning and visual appeal are important, such as control rooms. Matte finishes are preferred in settings where glare reduction and slip resistance are necessary, such as industrial floors or panels.Q: Where can these glass fiber composites be applied for electrical insulation?

A: They are commonly used as insulation panels in switchgear, control cabinets, and other electrical enclosures where high dielectric strength and fire resistance are essential for safety and reliability.Q: What is the process for cutting and mounting these composite accessories?

A: Accessories like cutting, drilling, and mounting components are designed specifically for the composites structure. Standard industrial tools can be used, and mounting is facilitated via pre-drilled holes or brackets for easy installation.Q: How does the control system compatibility benefit industrial users?

A: Compatibility with both PLC and manual control systems enables integration into automated or traditionally operated setups, offering flexibility for various industrial workflows and upgrade paths.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Composite Material Products Category

Composite Materials

Type : Fibre Reinforced Polymer

Surface Treatment : Polished

Application : Aerospace, Automotive, Construction

Material : Composite

Operating Pressure : 30 MPa

Technology : Hot Pressing

Composite Engineering Materials

Type : Structural Material

Surface Treatment : Smooth Finish

Application : Aerospace, Automotive, Marine, Industrial Components

Material : Fibre Reinforced Polymer (FRP)

Operating Pressure : Atmospheric

Technology : Composite Engineering

Send Inquiry

Send Inquiry