Composite Materials

Composite Materials Specification

- Accessories Type

- Supporting Fixtures

- Power Source

- Electric

- Technology

- Hot Pressing

- Surface Treatment

- Polished

- Accuracy

- High Precision

- Control System

- PLC

- Automation Grade

- Automatic

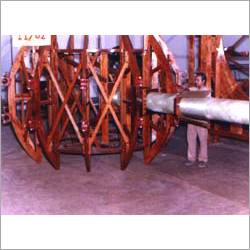

- Machine Type

- Fabrication Machine

- Operating Pressure

- 30 MPa

- Features

- Corrosion Resistant, Impact Proof, Customizable

- Type

- Fibre Reinforced Polymer

- Material

- Composite

- Function

- High Strength, Lightweight

- Application

- Aerospace, Automotive, Construction

About Composite Materials

We are engaged in offering glass reinforced composite, epoxy resin castings, cotton fabric composites, composites using combination of both glass and wood compreg.

Our products find application in almost every industry. The industries we have served in the past include -

| Electrical | Transformer, Switch Gear, Generator, Motor, Control Panel, etc. |

| Defence | Established Applications in Military, Navy & Air Force |

| Railways | Coach Buildings, Electrical Equipments, Traction Equipments, Rail Track components etc. |

| Automobile | Instrument Panel, Parcel Tray, Flooring, Under Bonnet Applications, Bumpers, etc. |

| Foundries | Match Plates & Pattern etc. |

| Forgings | Pattern Making, etc. |

| Textile machineries | Picking Sticks, etc for High Speed Automatic Looms. |

| Telecommunications | Underground Cable Covers & Casings, Joint Boxes, Telephone Booths etc. |

| Chemical | Pipelines, Tanks, Cryogenic Applications, etc. |

| Petroleum | Off-shore applications, pipelines, Non-corrosive doors, Partition, etc. |

| Construction | Doors, Flooring Material, etc. |

| Atomic Energy | Neutron Shielding Application. |

Advanced Technology and Performance

Utilizing high-precision fabrication machines with PLC control systems, our composites are manufactured through hot pressing, ensuring uniformity and durability. They undergo surface polishing to achieve both aesthetic appeal and enhanced performance characteristics.

Versatile Applications and Customization

Engineered specifically for demanding sectors like aerospace, automotive, and construction, our fibre reinforced polymers are customizable to client specifications. The lightweight yet highly strong design provides remarkable adaptability across diverse industrial uses.

FAQs of Composite Materials:

Q: How are these fibre reinforced polymer composites manufactured?

A: These composites are produced using a hot pressing technique in automated fabrication machines operated with a PLC control system. The process ensures high strength, lightweight properties, and precise dimensional accuracy.Q: What benefits do hot pressed, polished composites offer in industrial applications?

A: The hot pressing process combined with surface polishing provides high mechanical strength, resistance to corrosion and impact, lightweight construction, and a customizable finish, making them ideal for critical industries such as aerospace and automotive.Q: When should I choose fibre reinforced polymer composites for my project?

A: You should opt for these composites when your application demands a combination of high strength, lightweight, durability, and resistance to harsh environments, especially in aerospace, automotive, or construction projects.Q: Where can these composite materials be utilized?

A: These composite materials are well-suited for aerospace components, automotive structures, construction frameworks, and any other high-performance field requiring reliable strength and reduced weight.Q: What is the process for surface treatment of these composites?

A: After fabrication, the material undergoes a polishing process, enhancing surface smoothness and aesthetic quality while improving its resistance to environmental factors.Q: How does automation and high-precision fabrication benefit the product?

A: Automation using PLC controls ensures consistent quality and repeatability, while high-precision machinery guarantees that each composite component meets exact design and functional specifications.Q: What accessories are available with these composite materials?

A: Supporting fixtures are provided as accessories to complement installation and application, improving ease of use and versatility in various fabrication and assembly processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Composite Material Products Category

Glass Composite Materials

Type : Glass Fiber Reinforced Composite

Accessories Type : Cutting, Drilling, Mounting Accessories

Material : Glass Fiber, Resin

Function : High Strength Structural Support

Surface Treatment : Polished/Matte Finish

Application : Industrial, Construction, Electrical Insulation

Composite Engineering Materials

Type : Structural Material

Accessories Type : Customized as per Requirement

Material : Fibre Reinforced Polymer (FRP)

Function : High Strength & Lightweight Construction

Surface Treatment : Smooth Finish

Application : Aerospace, Automotive, Marine, Industrial Components

Send Inquiry

Send Inquiry